Bentonite cat litter technological process

Absorption and clumping of sodium bentonite cat litter

The production of cat litter is mainly composed of the following processes:

rough selection, drying, grinding, granulating, drying, screening and

packaging.

1Roughing

Natural soil water content 20%,shovel loader(mechanical loader) and sifter

pick out the stone with Diameter more than 20 centimeter.

2 Sun-cure(sun drying)

Transporting the finished roughing bentonite raw material to drying field,

through sun drying to make the water content 13-14%.

3、 Levigating (degradation in size)

Raymond machine grinding the sun dried bentonite raw material to 200 mesh.

4、 Granulation

Put the 200 mesh bentonite into the round granulating tray, water spout make

the bentonite powder to ball size 0.5-4.5 millimeter, which water content

15-20%.

5、Drying

Transporting the ball type bentonite granule to the cylinder via conveyor belt, drying to the water content 4%-5%.

6、 Screen(filter)、Packing.

Transporting the dried bentonite granule to the shaking screen to screen the

size which meet the requirement, then pack it, and sale.

Bentonite cat litter is popular for its clumping properties and natural odor control. Proper packing ensures that the litter remains effective and free from moisture. Here's a suitable packing method for bentonite cat litter:

1. Use Moisture-Resistant Packaging:

Pack the bentonite cat litter in moisture-resistant bags. Thick, durable plastic bags with a moisture barrier coating inside are ideal for preventing moisture from getting inside the packaging.

2. Sealed Bags:

Seal the bags tightly to prevent air and moisture from entering. Airtight sealing ensures the litter stays fresh and clumps effectively.

3. Avoid Exposure to Humidity:

Store the bentonite cat litter in a dry environment. Humidity can cause clumping in the package and reduce the litter's clumping effectiveness. Store the bags away from areas prone to moisture and humidity.

4. Desiccant Packs:

Include desiccant packs inside the bags to absorb any moisture that might be present. Desiccant packs help in maintaining the dryness of the bentonite cat litter.

5. Avoid Direct Sunlight:

Keep the packaged litter away from direct sunlight and heat sources. Exposure to sunlight can lead to condensation inside the packaging, making the litter damp.

6. Proper Labeling:

Clearly label the packaging with product information, including brand name, product name, quantity, and usage instructions. Proper labeling is essential for consumers to know how to use the product correctly.

7. Quality Control:

Implement quality control measures to ensure that the bentonite cat litter is of high quality before packing. Regular testing can help maintain consistency in the product's clumping and odor control properties.

8. Protective Palletizing (for bulk shipments):

If shipping in bulk quantities, palletize the bags properly. Use stretch wrap to secure the bags on the pallets and protect them from dirt, moisture, and other contaminants during transit.

9. Regularly Monitor Storage Conditions:

Regularly check the storage area to ensure that there are no leaks or environmental factors that might compromise the integrity of the packaging. Address any issues promptly to maintain the quality of the packed litter.

By following these packing methods, you can ensure that bentonite cat litter remains dry, clumps effectively, and provides optimal odor control for consumers.

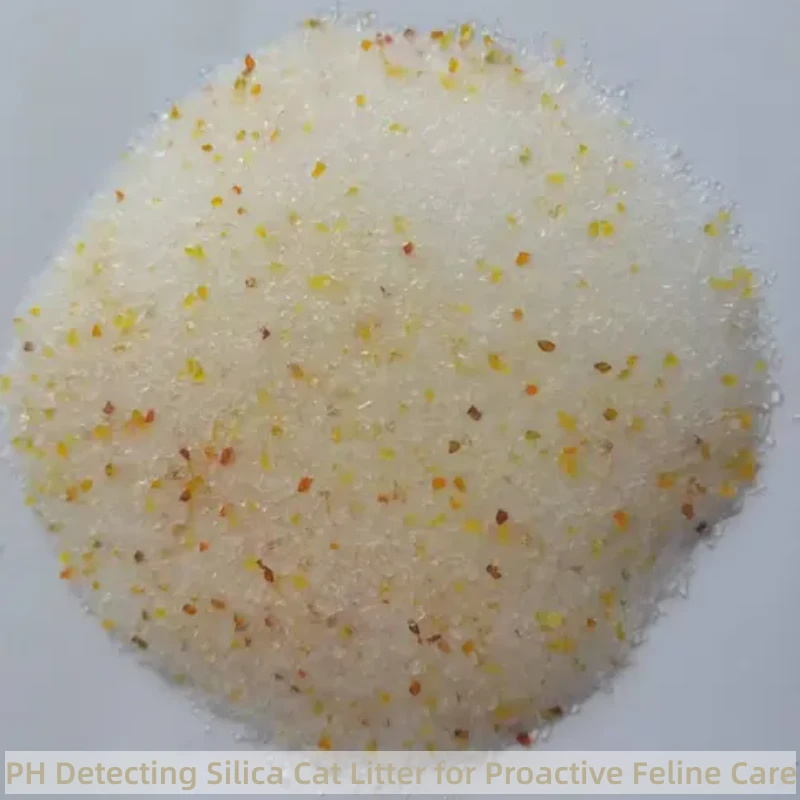

808.jpg)